Description

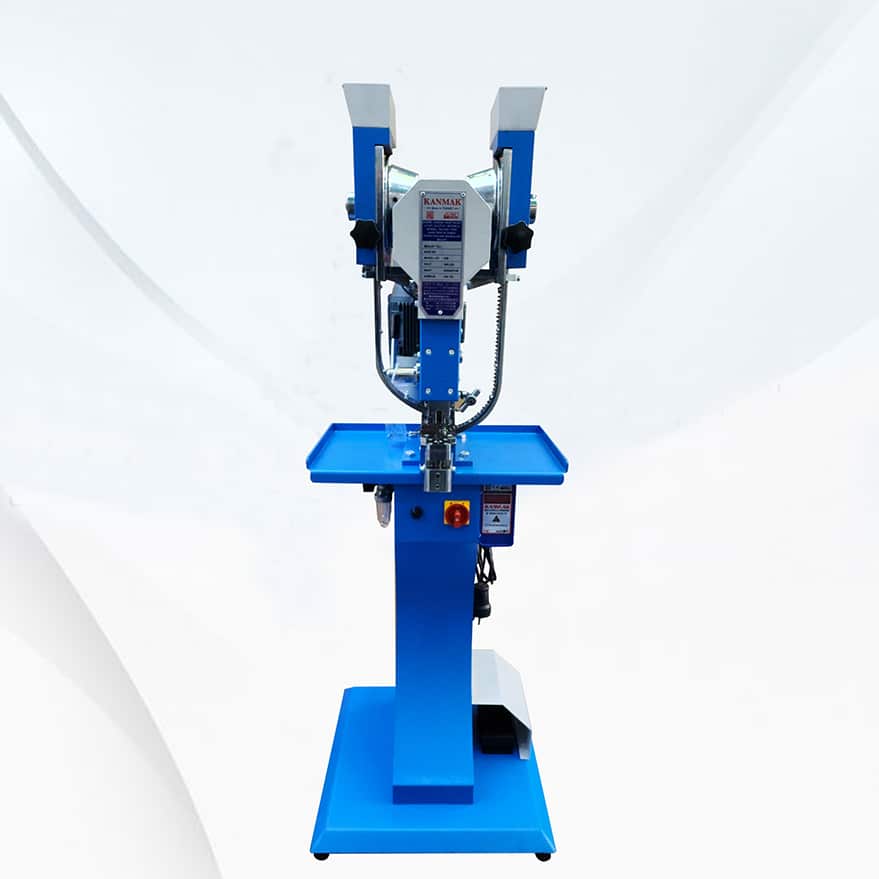

Automatic Cutting Machine Full Model KM 1850

Nonwoven Fabric Cutting Machine KM1850

Bias Cutting Machines

Automatic Bias Cutting Ball Fabric Slicing Machine

TECHNICAL DETAIL:

Automatic Bias Cutting Machine Full Model KM 1850 Bias Cutting Machines

Automatic Bias Cutting Ball Fabric Slicing Machine

Specially Produced for Hard Top Fabrics

Automatic Cutting Machine

Automatic Cutting Machine Full Model KM 1850

FELT

MACHINE CAPACITY:

Cutting Range: 1mm – 2000mm Cut Length 2000mm

Shaft Thickness Range: 3 inch

Max Diameter Width: 500mm

Cutting Sensitivity: + -00.1mm

Automatic Cutting (Slicing) Machine

FUNCTIONS:

Manual and half automatic use

LCD 7 inch color screen

Speed adjustment of all moving parts

Knife sharpening (pieces and time controlled)

Purulent spraying (quantity and time controlled)

Measure and cut pieces (5 pcs)

Engines forward and return

Automatic reset

500mm air steel blade

NONWOVEN SYSTEM

Nonwoven Fabric Cutting Machine

500MM KNIFE

MEASUREMENT SERVO SYSTEM MOTOR

TOUCH 7 INCH DISPLAY

OFF-CAB-PROTECTION-Hush my

WATER COOLING

11.5 KW

75 MM LİK ROLL ŞAFT

Automatic Cutting Machine Full Model KM 1850

7 inch PLC / OPERATOR PANEL

All mechanical and electrical hardware systems on the machine are in PLC control.

Touch screen operator panel with all functions on the machine can be operated and easy to use

Automatic Cutting Machine Full Model KM 1850

OTHER TOPICS:

RECEIVE INSTALLATION AND ACTIVATION:

1 mounting element is assigned by KANMAK MAKİNA.

You must notify your installation request at least 1 week in advance.

Intercity transportation expenses for domestic installations KANMAK MACHINERY company, accommodation expenses, transfers between hotels – businesses – hotels belongs to the company.

Min. 1.5 ton capacity of forklift truck belongs to the buyer.

For the purpose of assisting the installers during the assembly;

1 mechanical / 1 electrical personnel must be assigned by the BUYER.

Also, when necessary, 1 construction officer must be supplied.

Installation time max. 1 day.

For the use of our assembly staff, an office should be allocated if possible.

Before your installation request; the machine should be placed on the installation site, but the package should not be opened. The opened packages and their contents are out of warranty.

Electrical installation up to the board and the supply of the materials belong to the receiving company.

The supply of the air line up to the main conditioner and the supplies thereof belong to the receiving company.

The construction of the necessary construction operations belongs to the buyer.

WARRANTY AND SERVICE:

During the warranty period, the need for spare parts due to manufacturing defects is free. The warranty period is 12 months against manufacturing defects. This time starts on the day the machine is started up / on which the trial production begins. If the buyer is delaying the installation due to various reasons, the warranty period shall be extended up to 15 months from the end of the production.

The warranty of the consumable is covered by the warranty of its manufacturers.

After the expiry of the warranty period, the service is provided but the travel and accommodation expenses of the service personnel requested and the daily working fee and the material expenses to be used belong to the buyer. The working fee is determined according to the values at that time.

PACKAGING:

Partial packaging is made with carton, foam and strech film materials to prevent wear during transportation.

SHIPPING + INSURANCE:

Transport and insurance belong to the BUYER.

DELIVERY METHOD:

60 working days after receipt of order confirmation and advance payment FACTORY EXIT.

This period does not include delays that may be caused by imported material inputs and delays due to natural disasters.

Reviews

There are no reviews yet.